- Ygreenhouse™️

- CHINA

- One Month

- 100 Containers Per Month

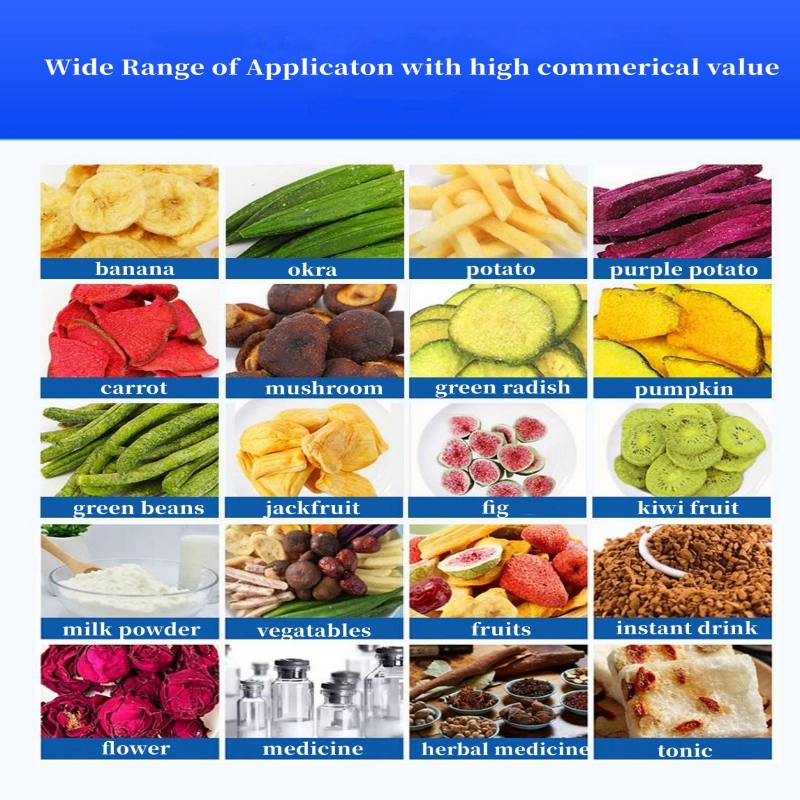

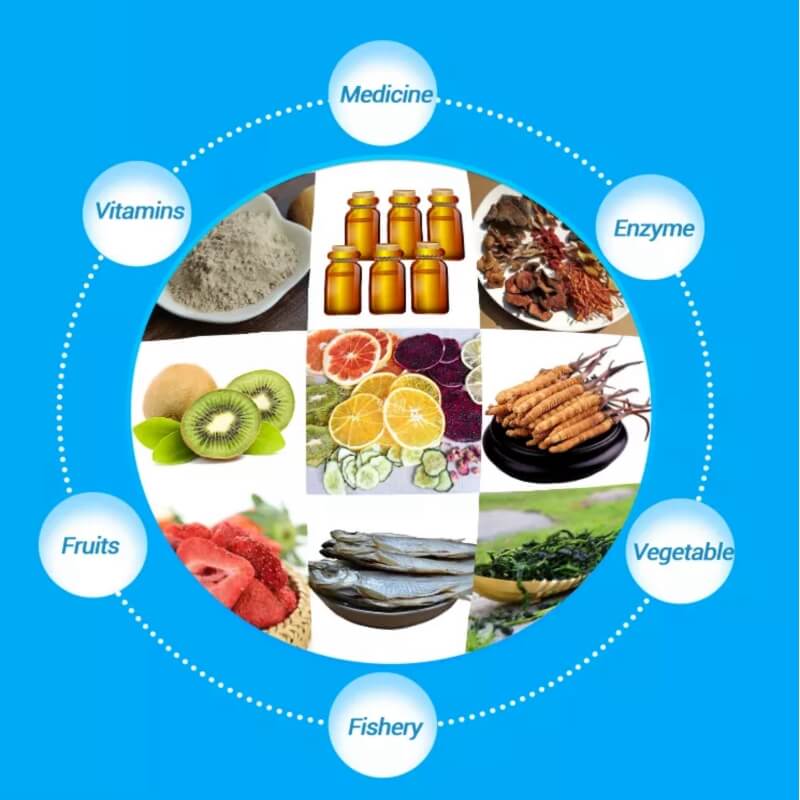

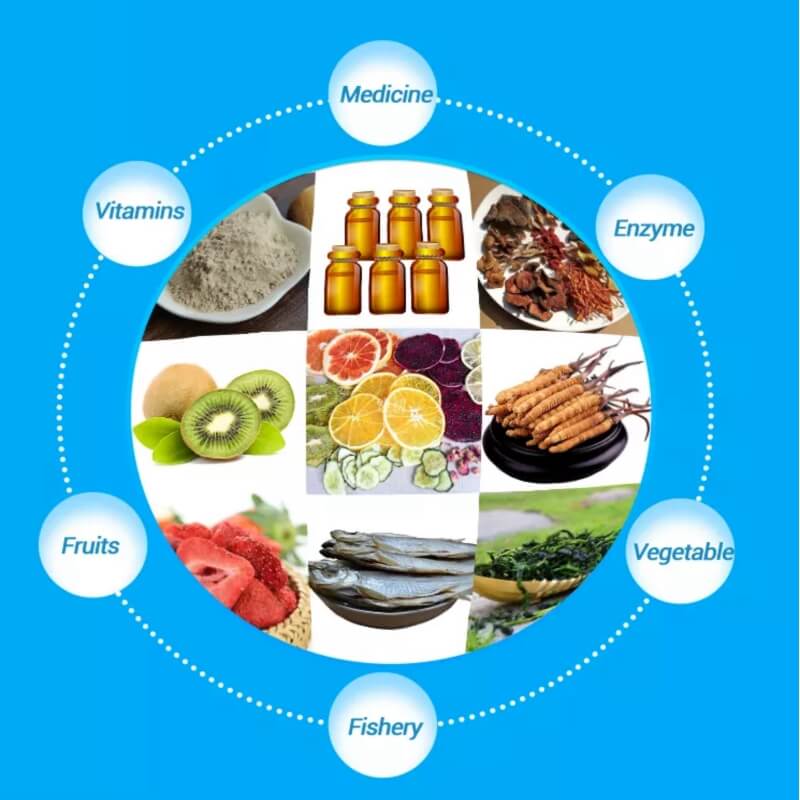

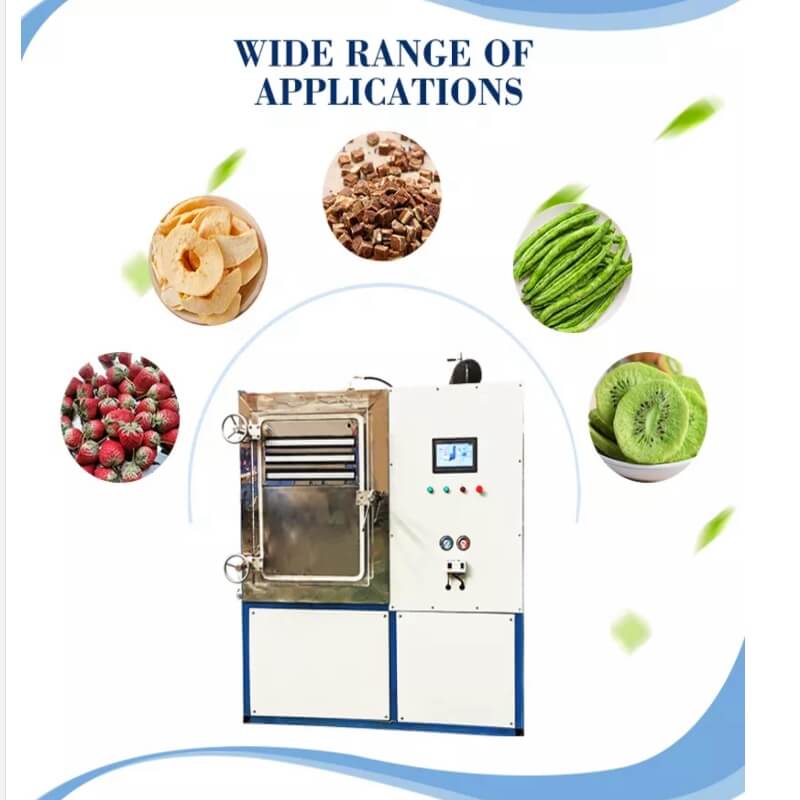

Vacuum Freeze Drying Machine is widely used in food, fruit, vegetable, fish, sea cucumer,shrimp, meat drying indstury, chemical and biological industry etc. The dried product by home freeze drying machine machine is with good taste, beautiful color and good shape.Compared with air drying, dehydration and other technologies, the biggest characteristic of freeze-dried food is to retain the color, aroma, taste, shape of the product and the nutritional composition of the original ecological food.

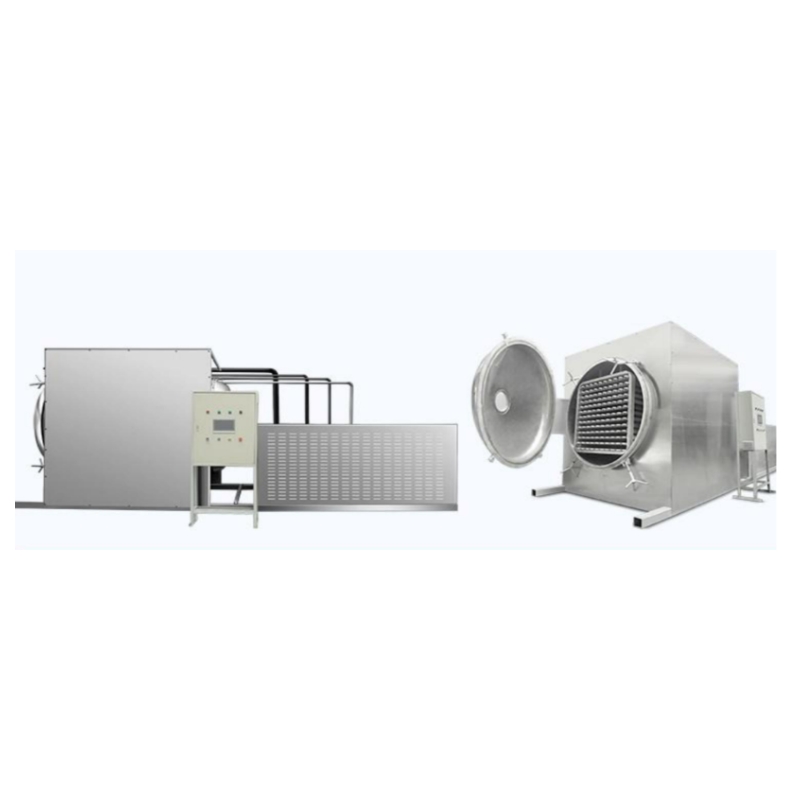

FREEZE DRY MACHINE

Features

1. Compact conformation, convenient maintain, low price, full automatic control and convenient operation;.

2. Multi-function, can be used in many materials, like food, fruit, vegetable, fish, sea cucumber, etc.

3. Excellect design, low energy cost, only need to work by using electricity.

4. Solid stainless steel sample tray and chamber reliable for sample safety and easy for cleaning.

5. Clear organic glass door with direct observation of sample processing.

Detailed

Product parameters | |||||||

Style Number | L5-0.6 | L5-1 | L5-2 | L5-3 | L5-4 | L5-5 | L5-6 |

Layer Area(m2) | 0.6 | 1 | 2 | 3 | 4 | 5 | 6 |

Layer Material Grade | SS 304 | ||||||

Quantities of Layer | 4+1 | 8+1 | 8+1 | 8+1 | 8+1 | 8+1 | 8+1 |

Layer Size(m) | - | 0.54*0.24 | 0.54*0.47 | 0.54*0.7 | 0.54*0.93 | 0 54*1.16 | 0 54*1.39 |

Materials weight reference(KG) | 6 | 10 | 20 | 30 | 40 | 50 | 60 |

Quantities of Material Tray | 4 | 8 | 8 | 8 | 8 | 8 | 8 |

Shape of Dry Container | cylinder | ||||||

Maerial Grade of Dry Container | SS 304 | ||||||

Heat Conduction Mode | Electrical Heating | ||||||

Layer Temperature | 0°C- + 100°C | ||||||

Vacuum | WIOPa | ||||||

Vacuum Pump (set) | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Cold trap temperature | N0°C~W-40°C | ||||||

Water Catcher Volume (KG) | 6 | 10 | |||||

Control Mode | Manual / Automatic program control | ||||||

Refrigeration Unit | 1HP | 1.5HP | 2HP | 3HP | 4HP | 5HP | 6HP |

Condensation Mode | Air Cooling | ||||||

Voltage | 220v/50Hz | 380v/50Hz | |||||

Outer Size Measurement (m) | 08*0.8*1 | 1.3*0.5*15 | 1.3*0.7*15 | 1.3*0.9*15 | 1.3*1.2*15 | 1.3*1.4*1.5 | 1.3*1.6*15 |

Refference Power | 2kw | 6kw | llkw | 15kw | 22kw | 25kw | 32kw |

Machine Design | Integrated design | ||||||

Others | customization is available | ||||||

Freeze-drying process

1. Wash and tidy.

2. Cut into slices, cut into pieces.

3. Lay flat on material tray and put into lyophilization chamber.

4. Set up the freeze-drying process, the equipment intelligent control operation.

5. After lyophilization, take out the sealed package.

Working Principle

The freeze vacuum dryer can remove the moisture in the pre-frozen material under the high vacuum state, it makes the moisture steamed under Ice state,don't have to melt into water.

The machine will pre-frozen the material and then creat high vacuum state to heat the materi to dry with low temperature. Which will best maintain the hysical properties and can keep long after drying compared with other drying ways.

Application

Packing and Delivery

Packing:

① All the steel material is nude packing;

② Motor and electric machines are put in carton;

③ Small steel parts are put in bag;

④ Glass is put in iron frame;

⑤ All the material is put in containers;

⑥ We provide clients world wide shipping with on-time delivery

Shipping:Sea Freight

Port: Xingang,China

Lead Time:Est. Time(days): 25 or To Be Negotiated

Delivery:Within 30 days after payment